Extrusion rounding machine

The extrusion spheronization machine is mainly applicable to the pellet preparation process. The working principle is to use the rotating screw to transport and extrude the wet raw materials to the ball cover, extrude the materials into long strips through the ball cover, and then use the high-speed rotating toothed disc to round the long strip materials into dense spherical pellets.

Category: Project Display

key word: Liquid Particle Processing System

TEL:

Extrusion rounding machine

Product introduction:

The extrusion spheronization machine is mainly applicable to the pellet preparation process. The working principle is to use the rotating screw to transport and extrude the wet raw materials to the ball cover, extrude the materials into long strips through the ball cover, and then use the high-speed rotating toothed disc to round the long strip materials into dense spherical pellets.

Pellets have been widely used in the field of pharmacy. As a drug carrier, it can not only be further pressed into tablets, but also be used in empty capsules. It not only improves the stability of drugs, but also can effectively adjust the drug release rate; As a drug delivery system, pellets have therapeutic advantages, such as less gastrointestinal irritation, reducing the risk of sudden drug release, improving drug safety, and good reproducibility of blood drug concentration; Pellets also have the advantages of good fluidity, low brittleness and easy filling.

In preparation production, compared with other pill making methods, extrusion spheronization technology is an advanced process widely used in the international preparation industry.

In terms of controlled-release preparations and drug availability, many factors in extrusion spheronization can change the powder properties and drug release behavior of pellets; The measurement indexes of pellet quality mainly include: pellet size, roundness, brittleness, density, fluidity, drug dissolution and microstructure of pellet surface. Through independent and careful investigation of various factors, the properties of pellets can be improved to achieve the expected drug use purpose.

Technical features:

★ the screw modes include double head equidistant screw, double head variable distance screw and combined screw. The modular screw selection can be applied to a variety of materials with different properties, with stronger applicability.

★ the extrusion barrel has a built-in cooling channel, which can effectively reduce the temperature rise in the extrusion process.

★ for the five axis processed ball cover, all holes are normal, with small resistance, low heating, smooth discharge and long service life.

● modular design, optional spherical extrusion, lateral extrusion and plane cutting extrusion.

● the extrusion ball cover adopts five axis drilling processing to make the material extrusion balanced and efficient.

● built in cooling channel for air cooling and water cooling.

● it is designed with material and cooling water temperature detection, extrusion current detection and overload current protection.

● three types of turntables (optical disc, orthogonal toothed disc and divergent toothed disc are optional) can be applied to the whole grain of a variety of materials with different properties.

● carry out process operation in a wet state to completely eliminate dust.

● high product yield, narrow particle size distribution, and qualified product rate up to 90%.

● high efficiency, low cost and low labor intensity.

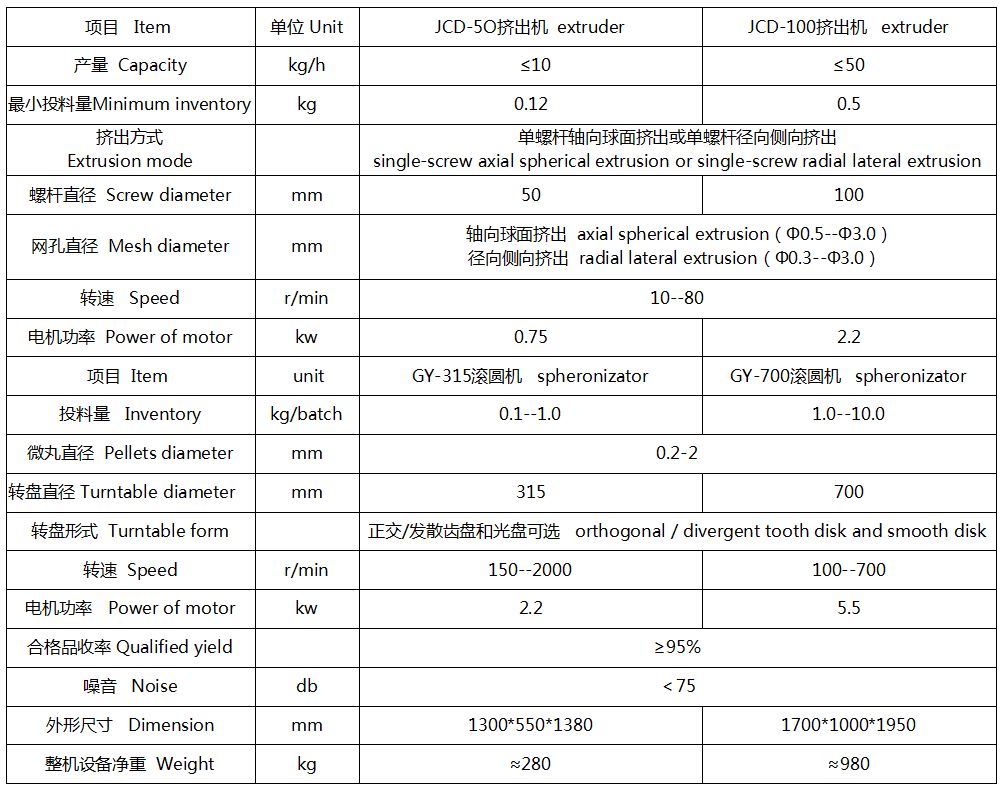

Technical parameters:

ONLINE MESSAG

——